For MTSU supply chain management professor Cliff Welborn, the ongoing coronavirus pandemic — and the resulting concerns about testing capacity, food supply and the scarcity of household items such as toilet paper and wipes — highlights the growing importance of his field of instruction and a key concept within it: “right product, right place, right time.”

Dr. Cliff Welborn

The university’s Supply Chain Management concentration within the Jennings A. Jones College of Business offers students training toward an emerging career field now at the center of critical conversations about how best to get needed supplies to eager, and in some cases anxious, customers whose activities have ripple effects on the wider economy.

The Department of Management offers a bachelor’s and master’s degree with a supply chain management concentration for those interested in areas such as purchasing, logistics, and inventory and materials management. The COVID-19 pandemic has put a spotlight on the importance of supply chains, lessons that Welborn has incorporated into his online classroom this almost completed spring semester.

“We are trying to take advantage of the learning situation,” said Welborn, a professor of supply chain management. “Many of the exercises in class this semester have involved supply chain issues right in the middle of this crisis, so we’re trying to get our students to solve problems that supply chain professionals are solving right now.”

Among those professionals is MTSU alumnus Chris Zilly of Murfreesboro, a supply chain manager for Nissan Group of North America. Zilly has overseen Nissan’s international warehouse operations for the past year and worked as a senior logistics analyst for two years before that. He credits his supply chain credentials from MTSU with helping him advance in his career.

“I think the entire world now sees what it takes to make a society run. Up until now, supply chain was kind of the behind the scenes career that nobody really understood the importance of,” said Zilly, who earned bachelor’s degrees in international relations and global studies (’07) and a master’s in supply chain management (’17) from MTSU.

Semi trucks are a critical part of supply chain management, an area that has become increasingly importance during the COVID-19 pandemic. (Photo by Mike from Pexels)

“Now, if you look around, most workers that are deemed essential are connected to supply chain. You have analysts trying to figure out lead times and reallocate distribution, warehouse managers working to figure out how to realign their workforces, front line technicians trying to meet the daily demand of the end customers,” he continued. “This really hit home for everyone when they went to the store and couldn’t buy toilet paper anymore.

“On a global level, I think people now understand how interconnected the world is. In 2008, the financial crisis highlighted bad business practices by different financial institutions. This crisis is highlighting how dependent each industry is on another. It’s showing the world that the entire economy can’t function without supply chains.”

Welborn said that while overall public and individual health remains the top priority as the pandemic continues, closely connected to that are concerns about acquiring sufficient quantities of COVID-19 testing kits and PPE such as masks and gowns for frontline health care workers. In recent weeks, Welborn noted, public focus has “kind of shifted into food a little bit more and people worrying about the meat supply.”

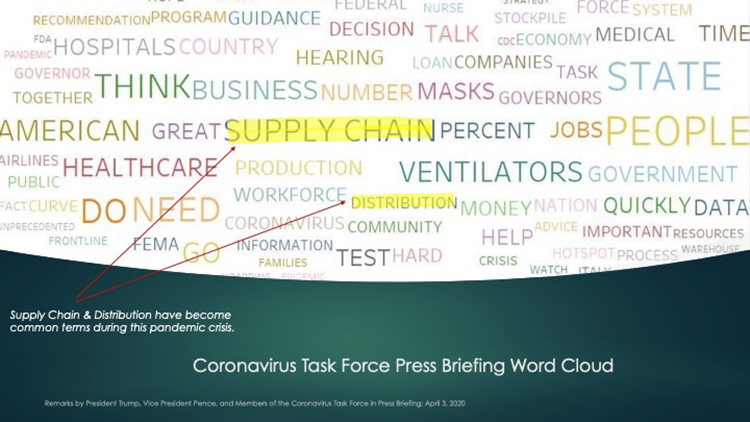

For his online course, Welborn created a word cloud slide that showed the most used words and phrases by President Donald Trump and Vice President Mike Pence during an early April briefing on the COVID-19 pandemic response. Among the most used words and phrases was “supply chain” and “distribution” as well as words related to supply chains such as “masks” and “ventilators.”

This word cloud created by MTSU supply chain management professor Cliff Welborn shows the most used words and phrases by President Donald Trump and Vice President Mike Pence during an early April briefing on the COVID-19 pandemic response. Welborn created this PowerPoint slide for one of his remote courses to illustrate the growing importance of supply chain issues during this global health crisis. (Courtesy of Cliff Welborn)

But supply chains can be long and complex, meaning factors such as lead times and manufacturing capacity must be taken into account when a sudden spike in demand happens, especially one that lingers like this one, Welborn added. Longer term, supply chain managers will be asked to analyze scenarios such as whether companies should have more local suppliers and why was there a shortage of items such as N95 masks.

“The supply chain can’t respond overnight. It’s like water coming through a pipe,” he said. “Supply chain folks are always looking at what disruptive forces are out there … but I don’t think anybody anticipated how extreme this (pandemic) situation would be.”

Zilly is thankful for his training at MTSU under Welborn and other professors in the program because the courses “were structured in a way that you could immediately take the course work and apply it to your job. Lots of other classes focus on theory and executive level management concepts. Those are eventually useful, but in supply chain, as in most things, you don’t start out at the top. You need that tactical, operational, front line knowledge to meet the daily challenges of getting products moved around the world.”

And based on daily news cycles, such as concerns about the meat supply chain, those challenges will certainly continue.

“There has never been a better time to be a supply chain professional than right now. There are headaches, sure, but we’re right in the middle of things,” Welborn said. “If you want to be part of the solution to this, and you’re watching all of this happen and are upset with how our lives are being disrupted, certainly health care is the place to go … but supply chain is right behind it.”

For more information about MTSU’s Supply Chain Management concentration, go to https://www.mtsu.edu/programs/management-supply-chain/ or call 615-898-2736.

— Jimmy Hart (Jimmy.Hart@mtsu.edu)

COMMENTS ARE OFF THIS POST