There’s a concrete True Blue connection to NASA’s plan to return to the moon in 2026 and establish a human settlement by 2035.

NASA selected the Marshall Space Flight Center in Huntsville, Alabama, to lead the federal agency’s lunar habitat project, a series of increasingly complex missions that will culminate in rocket flights from the moon to Mars.

Marshall in turn aligned with an elite group of commercial and academic partners nationwide to accomplish the mission—arguably the most ambitious construction project in human history.

Among them is MTSU’s renowned Concrete Industry Management (CIM) program, the oldest and biggest of its kind at a higher education institution in the nation.

CIM is taking the lead on the development of construction materials made from moon soil to build needed infrastructure, including habitats, landing pads, roadways, berms, and blast shields.

Said another way, MTSU’s concrete program is developing “moon beams” to build in outer space.

Click to see the most recent edition of MTSU’s Innovations magazine on the Foleon digital platform.

A True Blue Moon Print

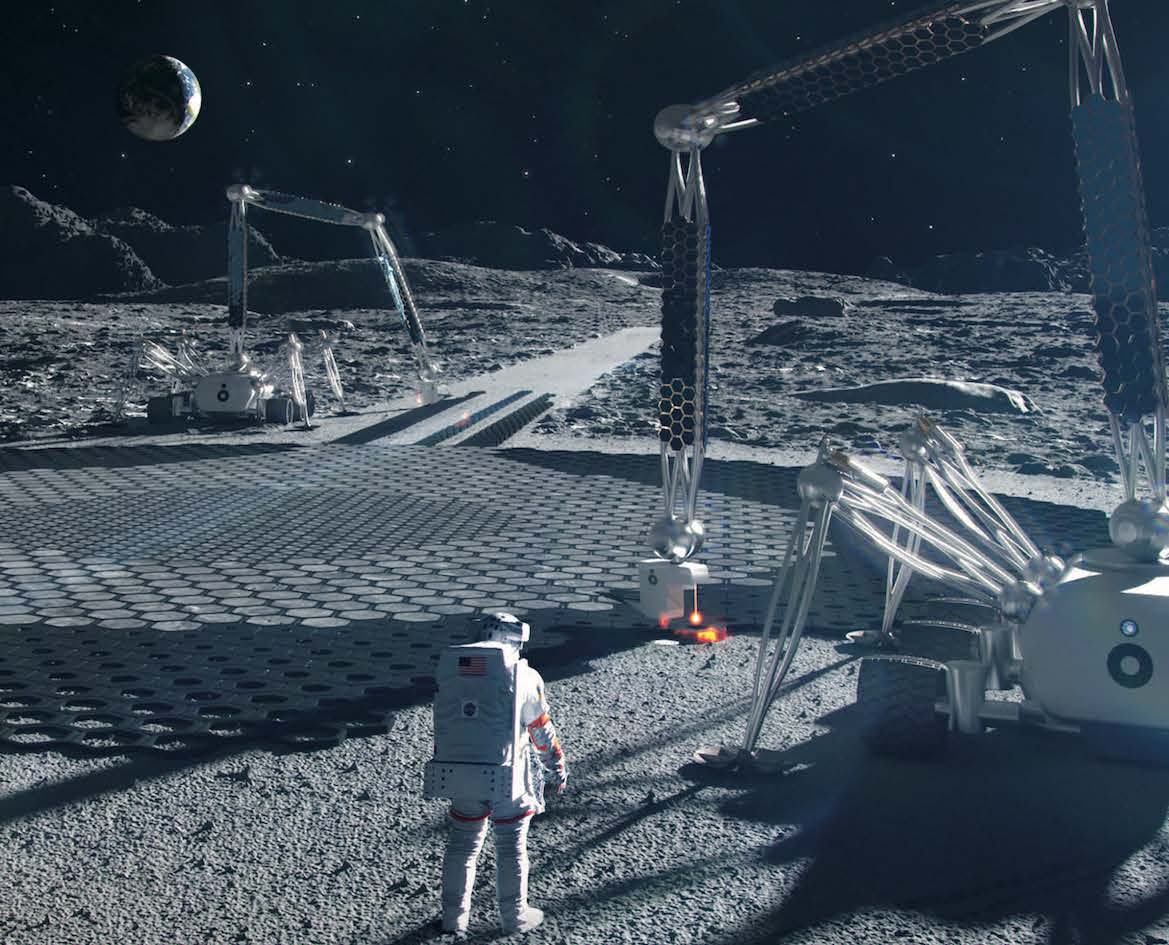

Building on the moon will look quite different from construction on Earth.

First of all, ferrying loads of construction materials to the moon is financially and environmentally dubious.

In fact, the only cargo NASA plans to send is a large umbrella-like structure to create an atmosphere in which astronauts can work (remember, there’s limited gravity on the moon) and a 3D printer to print structures.

All the raw materials needed for construction will be mined from the surface of the moon.

Enter MTSU. The good folks in Huntsville may be rocket scientists, but experts in concrete chemistry they are not. They smartly reached out to MTSU’s CIM program for help. Not surprisingly, it turns out there’s some unique chemistry involved in producing lunar construction materials.

MTSU is busily testing terrestrially manufactured “lunar” construction material, called regolith, created by the Colorado School of Mines. (The Apollo mission more than 50 years ago gave scientists a clear sense of the makeup of lunar soil.)

CIM’s goal? Perfect the use of regolith to build fail-proof “concrete” for lunar construction.

MTSU test batches of beams from lunar-like soil for NASA’s moon-to-Mars project (MTSU photo by Andy Heidt)

CIM has already produced “lunar beams” in campus labs using the simulate soil, which is the exact composition chemically and in particle size as lunar soil.

I call them moon beams,” said Kelly Strong, outgoing director of the School of Concrete and Construction Management at MTSU. “It’s not quite the moon beams you grew up singing about, but we have moon beams in our freeze chamber in our lab.

What’s different about these earthly moon beams? Regolith is very fine, almost powdery, compared to the mix of large rocks, small rocks, and powder used in standard concrete.

And unlike concrete, material made with regolith can’t be reinforced with steel. CIM solved that problem by printing latticework to give it some rigidity.

Early mixes were too soupy to print. When it came out of the printer, it just kind of puddled. There was no way to build volumetrically with that. So, testing continued. Eventually, CIM got the consistency right. But then, when it did another print and the regolith material settled, the moon beams began cracking deep into the structure.

The quest continues. Working in partnership with Drake State Technical and Community College in Huntsville, which is close to Marshall Space Flight Center and has a concrete printer, CIM was at press time working to embed structural health monitors inside its next batches of moon beams to monitor them for six months. Meanwhile, the clock is ticking on 2035.

Fly Me to the Moon

Hundreds of millions of people watched humanity’s first step onto the lunar surface on July 20, 1969.

NASA boasts that technologies like breathing apparatuses, fabric structures, communications, and protective coatings that made a human’s step on the moon possible soon led to giant leaps in technology on Earth.

Examples range from firefighting equipment improvements to seismology advancements to the development of heart monitors, solar panels, and more. People forget how many technologies came out of the Apollo mission—technologies we now use every day.

The same will no doubt be true of this latest project. Everything the Marshall Space Flight Center project is doing for the current lunar application could have a terrestrial application.

That applies to CIM’s portion of the work as well.

One possible outcome, according to Strong, could be the acceleration of the use of 3D printers to print structures on Earth in response to critical labor shortages in the construction industry.

I don’t think we can, in the long term, afford to use scarce labor resources to place urban gutter,” he said. “Simple concrete structures, I think, are eventually going to be printed, as will storage units and other things like that, just because there’s not enough labor to go around.

Strong added that current cement production techniques tend to be carbon intensive. Alternative materials, as well as different manufacturing or production technologies, could lessen the impact.

“Some of what we learn from using these literally alien technologies on the moon might be able to be applied on the Earth to reduce the carbon footprint of concrete as well,” he said.

Aligned with MTSU’s core mission to prepare students for the jobs of the future, CIM’s involvement in the NASA project smartly provides an out-of-this-world learning experience for students.

NASA grants currently pay four CIM students to serve as interns on the moon beams project.

“It’s just a fantastic opportunity for our students to learn about this technology,” Strong said. “And that’s the right thing to do. It can’t just be a bunch of people with Ph.D.’s at Cape Canaveral that are running this thing. We have to bring a new generation into the fold.”

Working on . . . working on the Moon

NASA is going to the moon to build a human settlement and launch spacecraft from there to Mars. It needs build-ing materials to accomplish the mission and has turned to MTSU’s Concrete Industry Management program to help supply answers.

How do you build a settlement in an atmosphere-less environment? Where do you get air to breathe and to propel rockets? What about water? Don’t you need water to mix with lunar dust to produce “concrete”? And how are you going to accomplish all of this in utter darkness?

AIR

Astronauts on the moon will need to have an atmosphere around them to print the concrete. That atmosphere is going to be created using a structure that will land on the moon and inflate.

Imagine your patio umbrella that you crank open. Well, NASA is effectively going to send the world’s largest patio umbrella to the moon. It will plant itself, anchor itself down, then fold out much like a patio umbrella does.

Astronauts will then create an atmosphere inside (about 0.6 Earth’s atmosphere). The robotic printer that also will be launched to the moon will operate inside this structure and print the infrastructure.

WATER

There is ice encapsulated on the southern pole of the moon, the dark side of the moon, which never gets sun. The ice there never melted when the moon ripped away from the Earth a long, long time ago.

Astronauts are going to melt some of that and mix it with the moon dust to make “concrete.” That water is also going to be excavated and separated into hydrogen and oxygen. The hydrogen will be used as the rocket fuel to launch rockets to Mars. The oxygen will be used to keep the astronauts alive.

LIGHT

Much of this work will be autonomously controlled from Earth using radio signals and lots of cameras to move rovers around and build launch pads and such. There won’t be truck drivers on the moon, at least not just yet.

COMMENTS ARE OFF THIS POST