Middle Tennessee State University and Tecport Optics of Orlando, Florida, have entered into a licensing agreement to commercialize the university’s biosensor technology as a medical diagnostic tool for research labs and point-of-care health professionals.

“The biosensor technology, which can be applied in the development of a variety of new and innovative sensing equipment, has the capability of revolutionizing medical diagnostics,” said MTSU professor Bill Robertson, the inventor and a member of the Department of Physics and Astronomy faculty.

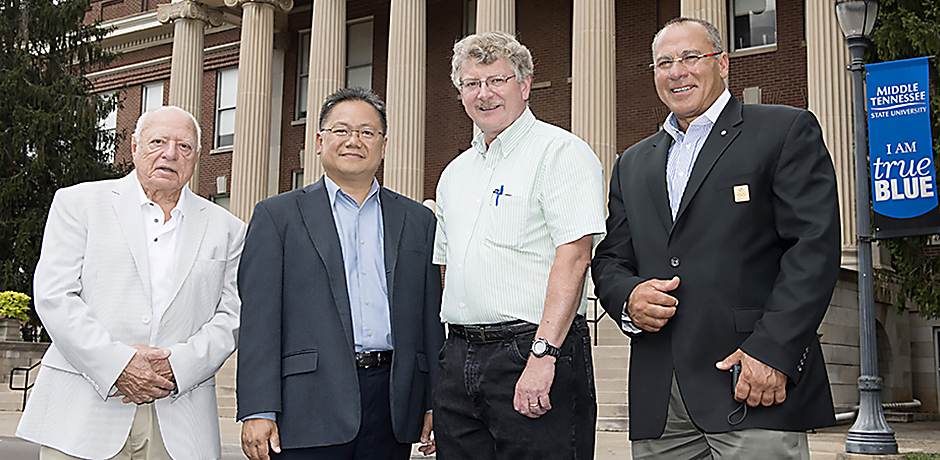

MTSU physics and astronomy professor Bill Robertson, shown at center right, is joined by Tecport Optics sales executive Frank Helmes, left, Tecport President Tam Lee and Tecport Vice Chairman Nabil El-Hag in front of Kirksey Old Main at MTSU. A licensing agreement between MTSU and Tecport will commercialize an innovative diagnostic tool, invented by Robertson, for medical research and health professionals. (MTSU photo by J. Intintoli)

An interdisciplinary team from MTSU including Drs. Robertson, Steve Wright of the Department of Biology and Andrienne Friedli of the Department of Chemistry developed the new technology with support from the National Science Foundation and the Department of Homeland Security.

“The growth of personalized medicine creates a pressing need for faster and better ways of diagnosing diseases and individual responses to pharmaceutical treatment,” he added. “In addition, drug discovery can be shortened when a rapid and more accurate way of screening for biological changes can be used in the process.”

The technology is based on specially designed multilayers, alternating thin films of silicon dioxide and titanium dioxide of precise thicknesses coated on a glass microscope slide.

The technology is based on specially designed multilayers, alternating thin films of silicon dioxide and titanium dioxide of precise thicknesses coated on a glass microscope slide.

These multilayers support electromagnetic waves that travel along the surface and detect extremely small changes, such as the addition of one layer of protein or antibody molecules on slide surfaces.

On appropriately prepared slides, such changes could indicate the identifiable markers of specific diseases.

“With the increase of disease-resistant bacteria and new strains of viruses killing over 700,000 people worldwide each year, speeding up the drug discovery process is an urgent priority,” Robertson said.

Dr. Nabil El-Hag, Tecport’s vice chairman and architect of the strategic relationship, noted that the project’s “long-term goal is to use biosensor technology as a mainstay in point-of-care medical diagnostics, not only in doctors’ offices and clinics, but in the local drugstore. This represents an opportunity to participate in the fast-growing $40 billion-plus medical diagnostic market.

“In Third World countries, where access to health care is often inaccessible, our biosensor technology could speed up and reduce the cost of diagnosis and treatment,” he added.

Tecport’s “cold plasma” thin film technology allows affordable fabrication of the multilayers, so that they can be used as a disposable supply for a biosensor.

Founded in 1977, Tecport designs, manufacturers, sells and services state-of-the-art thin film vacuum deposition systems to customers across the globe. The company builds efficient flexible coating systems customized to meet the technical specifications of a variety of industries. For more information, visit www.tecportoptics.com.

— Randy Weiler (Randy.Weiler@mtsu.edu) and Jimmy Hart (Jimmy.Hart@mtsu.edu)

COMMENTS ARE OFF THIS POST